The Vulcanizer for Rubber Conveyor Belt Maintenance and Care Guide

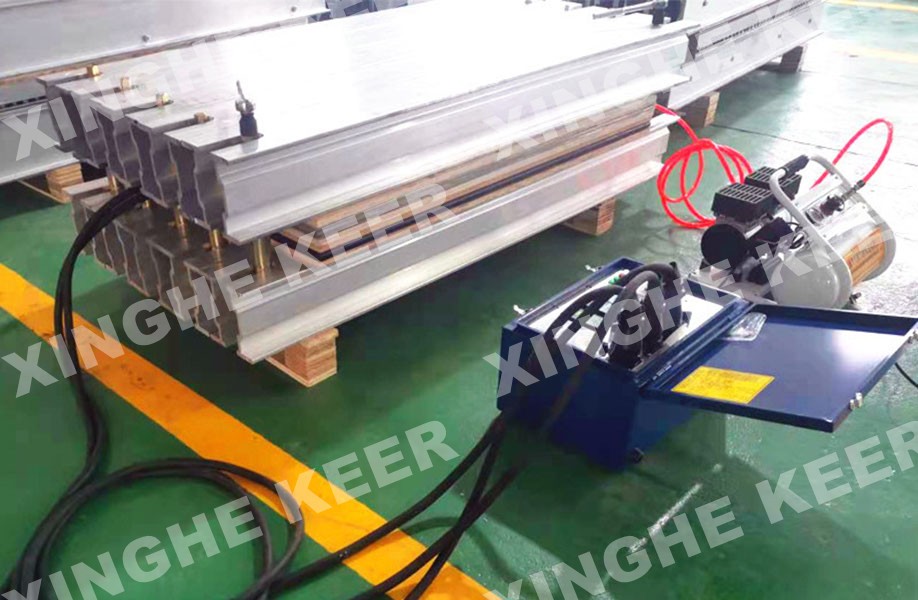

The vulcanizer for rubber conveyor belt is one of the indispensable and important equipment in the industrial production process, especially in the fields of logistics, mining, electric power and other fields. It uses a high-temperature and high-pressure vulcanization process to quickly and stably connect conveyor belts, ensuring the continuity and efficiency of the production line. Our company's products mainly produce assembly conveyor belt vulcanizing machines and integrated conveyor belt vulcanizing machine. In order to give full play to the performance of the conveyor tape vulcanizing splicing machine and extend its service life, this article will introduce in detail the maintenance and care guidelines for the equipment.

Daily maintenance methods

Cleaning: Regularly clean dust and debris on the surface of the equipment to keep the equipment clean.

Inspection: After every day's work, check whether all parts of the equipment are normal, especially the working status of the heating plate and vulcanizer.

Maintenance: Lubricate the equipment regularly to ensure the smooth operation of all moving parts.

Regular maintenance steps

Replace lubricating oil: Replace the lubricating oil of the equipment every quarter to ensure the smooth operation of the equipment.

Component inspection: Regularly check the wear and tear of each component, and replace them promptly if any abnormalities are found.

Maintenance: Conduct comprehensive inspections and repairs on the equipment regularly to ensure the overall performance of the equipment.

The integrated conveyor belt vulcanizing machines produced by our company have been exported to more than 20 countries and regions such as South America and the Middle East, and are very popular among users.