The assembly conveyor vulcanization machine is an efficient equipment that integrates advanced technology and environmental protection concepts. It has a modular design for easy maintenance and upgrades. At the same time, it uses an intelligent control system to achieve accurate temperature control and time management, effectively improving work efficiency.

The biggest advantage of this product is its robustness, long service life, reduced frequency of replacement, and reduced operating costs. Moreover, its material selection is exquisite, has good corrosion resistance and oxidation resistance, and can maintain the best performance in a variety of harsh environments.

In addition, the maintenance of the assembly conveyor belt vulcanization machine is simple and can be completed with simple tools and materials. This not only saves a lot of maintenance costs, but also greatly improves production efficiency.

| Main Technical Features | |

| Heating method | electric heating |

| Pressure mode | water pressure |

| Control power supply voltage | 220V |

| Heating power | ≥7000W/m² |

| Equipped with digital temperature control system, vulcanization temperature 0-199℃, adjustable | |

| Heating time (temperature rise to 145℃) ≤20 minutes | |

| Vulcanization pressure can be set ≤2MPa | |

| Fully automatic control for temperature rise, heat preservation and temperature over-limit protection | |

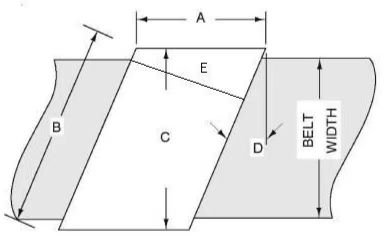

A=length of plate along the belt

B=width of plate across the belt on the bias

C=Right angle dimension across the belt, plus edge overlap.

D=Bias angle (0°/18°/20°/22°…..etc.)

E=Max Splice length

| Specifications of the Assembly Conveyor Belt Joint Vulcanizing Machine | D=22 degree | |||||||

| Model | Max Belt width(mm) | Max Splice Length E(mm) | Press Dimensions | Power(kw) | Weight(kg) | |||

| A(mm) | C(mm) | B(mm) | External dimension(L×W×H)(mm) | |||||

| 650×500 | 650 | 500 | 535 | 790 | 870 | 1080×730×630 | 6.1 | 280 |

| 650×670 | 650 | 670 | 707 | 790 | 870 | 1080×900×630 | 8.2 | 300 |

| 650×750 | 650 | 750 | 790 | 790 | 870 | 1080×980×630 | 9.1 | 320 |

| 650×830 | 650 | 830 | 872 | 790 | 870 | 1080×1050×630 | 10.1 | 380 |

| 650×1000 | 650 | 1000 | 1045 | 790 | 870 | 1080×1220×630 | 12.2 | 410 |

| 800×500 | 800 | 500 | 535 | 940 | 1020 | 1280×730×630 | 7.1 | 380 |

| 800×670 | 800 | 670 | 707 | 940 | 1020 | 1280×900×630 | 9.6 | 410 |

| 800×750 | 800 | 750 | 790 | 940 | 1020 | 1280×980×630 | 10.7 | 420 |

| 800×830 | 800 | 830 | 872 | 940 | 1020 | 1280×1050×630 | 11.9 | 460 |

| 800×1000 | 800 | 1000 | 1045 | 940 | 1020 | 1280×1220×630 | 14.3 | 490 |

| 1000×500 | 1000 | 500 | 535 | 1140 | 1220 | 1480×730×630 | 8.5 | 420 |

| 1000×670 | 1000 | 670 | 707 | 1140 | 1220 | 1480×900×630 | 11.4 | 500 |

| 1000×750 | 1000 | 750 | 790 | 1140 | 1220 | 1480×980×630 | 12.8 | 520 |

| 1000×830 | 1000 | 830 | 872 | 1140 | 1220 | 1480×1050×630 | 14.2 | 550 |

| 1000×1000 | 1000 | 1000 | 1045 | 1140 | 1220 | 1480×1220×630 | 17.1 | 590 |

| 1200×500 | 1200 | 500 | 535 | 1340 | 1420 | 1680×730×630 | 9.9 | 510 |

| 1200×670 | 1200 | 670 | 707 | 1340 | 1420 | 1680×900×630 | 13.3 | 550 |

| 1200×750 | 1200 | 750 | 790 | 1340 | 1420 | 1680×980×630 | 14.9 | 590 |

| 1200×830 | 1200 | 830 | 872 | 1340 | 1420 | 1680×1050×630 | 16.5 | 610 |

| 1200×1000 | 1200 | 1000 | 1045 | 1340 | 1420 | 1680×1220×630 | 19.1 | 650 |

| 1400×500 | 1400 | 500 | 535 | 1540 | 1620 | 1880×730×730 | 11.3 | 690 |

| 1400×670 | 1400 | 670 | 707 | 1540 | 1620 | 1880×900×730 | 15.2 | 720 |

| 1400×750 | 1400 | 750 | 790 | 1540 | 1620 | 1880×980×730 | 17.0 | 750 |

| 1400×830 | 1400 | 830 | 872 | 1540 | 1620 | 1880×1050×730 | 18.8 | 780 |

| 1400×1000 | 1400 | 1000 | 1045 | 1540 | 1620 | 1880×1220×730 | 22.7 | 850 |

| 1600×500 | 1600 | 500 | 535 | 1740 | 1820 | 2080×730×730 | 12.7 | 830 |

| 1600×670 | 1600 | 670 | 707 | 1740 | 1820 | 2080×900×730 | 17.1 | 880 |

| 1600×750 | 1600 | 750 | 790 | 1740 | 1820 | 2080×980×730 | 19.1 | 920 |

| 1600×830 | 1600 | 830 | 872 | 1740 | 1820 | 2080×1050×730 | 21.2 | 940 |

| 1600×1000 | 1600 | 1000 | 1045 | 1740 | 1820 | 2080×1220×730 | 25.5 | 1010 |

| 1800×500 | 1800 | 500 | 535 | 1940 | 2020 | 2280×730×730 | 14.1 | 880 |

| 1800×670 | 1800 | 670 | 707 | 1940 | 2020 | 2280×900×730 | 19.0 | 920 |

| 1800×750 | 1800 | 750 | 790 | 1940 | 2020 | 2280×980×730 | 21.2 | 950 |

| 1800×830 | 1800 | 830 | 872 | 1940 | 2020 | 2280×1050×730 | 23.5 | 1050 |

| 1800×1000 | 1800 | 1000 | 1045 | 1940 | 2020 | 2280×1220×730 | 28.3 | 1150 |

| 2200×500 | 2200 | 500 | 535 | 2340 | 2420 | 2680×730×820 | 16.9 | 1020 |

| 2200×670 | 2200 | 670 | 707 | 2340 | 2420 | 2680×900×820 | 22.7 | 1190 |

| 2200×750 | 2200 | 750 | 790 | 2340 | 2420 | 2680×980×820 | 25.4 | 1310 |

| 2200×830 | 2200 | 830 | 872 | 2340 | 2420 | 2680×1050×820 | 28.1 | 1460 |

| 2200×1000 | 2200 | 1000 | 1045 | 2340 | 2420 | 2680×1220×820 | 33.9 | 1590 |

| Place of Origin | Qingdao City, China |

| Brand Name | XINGHE KEER |

| Certification | CE, ISO |

| Packaging and Transport Way | Plywood Box by Sea |

| Minimum Order Quantity | 1 Set |

| Supply Capacity | 50 Sets Per Month |

| Payment Terms | T/T |

| Delivery Time | 3 ~4 Weeks |

| Warranty | 12 Months |

We offer an extensive range of conveyor belt vulcanization joint machine, conveyor belt repair machine & electric pickling machine that are perfectly suited for a variety of mining machine operating environments